Effects of Excessive Ultrasonic Processing

It has long been an industry practice of post-decap cleaning an integrated circuit via ultrasonic. This process is done for multiple reasons. Decapsulation done through wet-chemical processing, like the JetEtch, can result in residue on the surface of the die and bond wires. While this residue doesn’t necessarily need to be removed, it can inhibit visual inspection. It is also common to have small patches of remaining mold compound present post-decap and instead of running additional decap time and risking damage, ultrasonic can be a big help in removing those small patches while also cleaning the internal structure for additional inspection/testing.

Because ultrasonic cleaning works via high frequency vibration, the amount of processing done can result in damage to the internal structure that would be otherwise avoided if your decap recipe can be adjusted. In the case of wet-chemical decap, the more time a sample is in contact with chemicals the higher the risk of damage, especially when delicate materials like copper bonding are present. Ultrasonic cleaning can be extremely helpful in these cases because it can mean less processing in the harsh environment that is wet-chemicals. It is because of these potential issues that an end-user must balance proper recipe development that will be fast while limiting damage.

Regardless of how well a recipe is developed, the necessity of post decap cleaning may still be needed but what do you do if that post decap cleaning means inducing damage to your sample?

The Nisene PlasmaEtch works off of microwave induced plasma (MIP). This process is considered to be a much more “clean” method of decapsulation. Not only does this process not result in a residue build-up on the internal sample structure, it means the necessity of post-decap cleaning can be drastically reduced, if not eliminated.

If a clean internal surface is required, do you risk potential damage? What if that same sample can be processed with MIP plasma and not require ultrasonic cleaning, would you be interested in adding this to your decapsulation capabilities?

![]() Figure 1: Metal Lift Example from Ultrasonic Bath

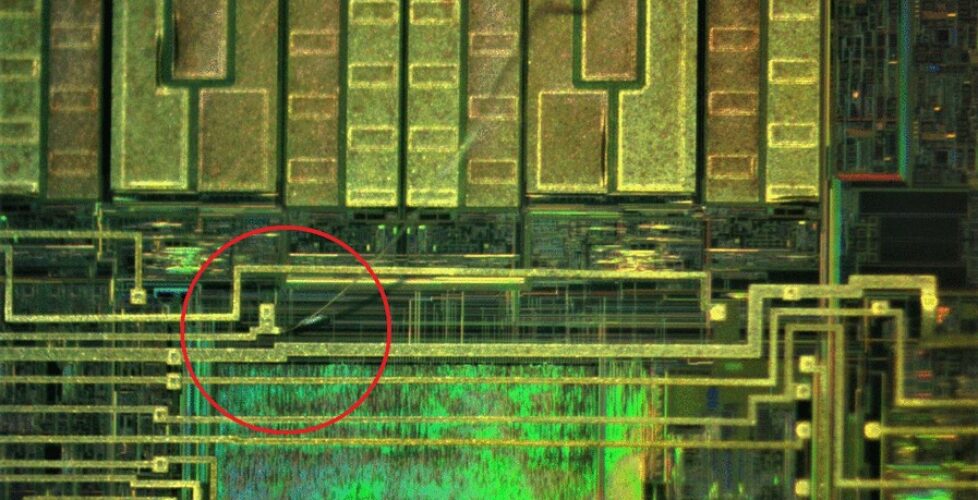

Figure 1: Metal Lift Example from Ultrasonic Bath

Figure 1 shows what excessive ultrasonic cleaning can mean.

But how much is excessive? 2 minutes? 5 minutes? 30 minutes? The sample in Figure 1 and Figure 2 received 10 minutes of post-decap cleaning in an ultrasonic.

![]() Figure 2: Metal Lift Example from Ultrasonic Bath

Figure 2: Metal Lift Example from Ultrasonic Bath

If your decap process required ultrasonic processing in order to work, would these type of results be accepted in your lab?

The Nisene PlasmaEtch allows for industry leading process gas control so that you as an end-user can adjust your recipe to where post decap cleaning is eliminated or minimized to the shortest period possible.

While ultrasonic cleaning can be incredibly helpful, the Nisene PlasmaEtch was designed to allow its users to achieve the cleanest internal process possible without the use of ultrasonic cleaning.

Similar plasma technology on the market heavily relies on ultrasonic because of the gases used in their process. How will those processes work for you if ultrasonic is causing damage to your components?

![]() Figure 3: PlasmaEtch Decap without Ultrasonic

Figure 3: PlasmaEtch Decap without Ultrasonic

Figure 3 shows the results at the die level of a sample that received no post-decap cleaning. This sample was taken straight out of the PlasmaEtch and under a microscope for imaging.

Are you looking to duplicate these type of results in your lab? Or maybe you want to see how your samples will look after processing here in our lab?

Contact Nisene Technology Group to coordinate samples or for additional info!